Proofing ovens are needed for many professional bakers, patisseries and bread bakers. They allow bakers to ensure that their dough rises properly and keeps its shape before it goes in the oven.

Here’s a look at why proofing ovens are so essential when baking professionally, how they work and what to look for when purchasing one.

Why Bakers Need a Proofing Ovens

Proofing is an essential part of baking and a process most people don’t do at home. The key goal of proofing is allowing your dough to relax and rise, which influences the way it will bake in the end product.

A good proof results in better shaped loaves, increased rise potential aided by added air pocket structures present in the loaf thanks to relaxation of gluten developed during rising, and larger porous crumb or interior structure desired by many consumers today.

The amount of time you proof your bread is critical; if left too long the interior will become over proofed, which can result in collapsed loaves.

This means that bakeries need some control over their dough’s environment if they want consistently quality results.

How Proofing Ovens Work

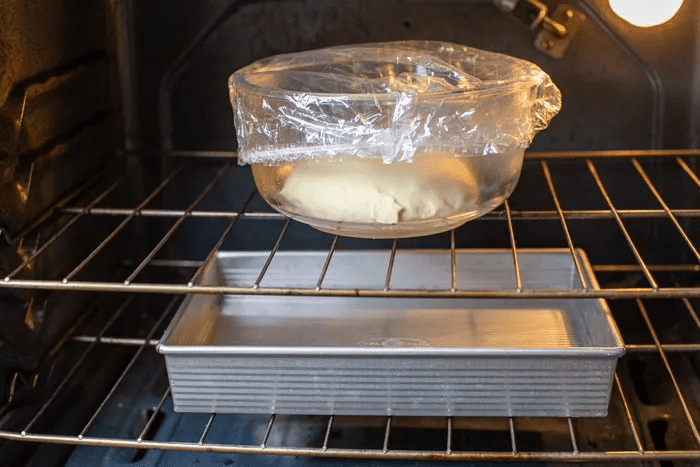

Proofing ovens provide controlled environments with temperatures ranging from 64°F to 100°F (17-38°C) and relative humidities usually between 50%-70%.

Different pieces of equipment can be used depending on your production workflow; you might prove everything directly within an insulated cabinet (sometimes called retarders), or use temperature-controlled slatted trays which sit above each other in large metal frames that can hold hundreds of loaves or rolls per rack (prover/proofer cabinets).

If needed, certain bakery customers will configure two metal frame units together with a humidity injector system built-in as well as monitors and timers fitted inside them to track the progress of the baking cycle.

purchaser should consider factors like durability, temperature regulation, size capabilities according to specific workload needs, timer functions etc before making any purchase decisions

What To Look For When Buying a Proofing Oven

When choosing a proofer oven there are many factors such as price point, budget limitations for installation costs if any build out tweaks have to occur either inside or outside since this device come supervised already built together but need adequate space to work effectively .

Potential buyers should also consider factors like durability – check material thicknesses & construction methods), temperature regulation accuracy & consistency across all parts during hot & cold cycles, size capabilities according to specific workload needs / production volume requirements now versus future plans .

Additionally user friendly controls such as timer functions , maintenance free aspects etc need careful attention so that operations by non technical staff members who may understand basics about these devices goes through smoothly since repair visits require considerable financial resources & time loss .

Types of Proofing Ovens

Proofing ovens come in three common types. The most basic type is made with only heating elements— no fan— which makes controlling humidity difficult. More expensive models contain heating elements and fans that allow better control of humidity.

The third type is steam injection ovens that use direct liquid injection into the cooking chamber to create steam and raise relative humidity levels quickly.

Modernization of Technology Relating with Proofing Ovens

Recent advances in technology have allowed chefs greater control over their dough’s environment when using a proofing oven.

This is made possible through the integration of advanced computerized controls that allow bakers to monitor factors like temperature, humidity, and fermentation rate from inside the baking area or remotely via an app on their smartphone or tablet device.

Additionally, some models feature automatic settings for specific recipes that can be activated just by entering the appropriate code or setting on the digital display panel at the bottom of the unit – simplifying repetitive tasks dramatically!

Conclusion

In conclusion, proofing ovens are important pieces of equipment for master bakers looking for consistent high quality results in their baked goods.

When selecting one it’s important to factor things like cost effectiveness , capacity , easy usage features & maintenance responsibilities unlike regular repairs & services while being reliable at every step .

Aspiring professionals must keep these points in mind while considering equipment purchases .

Leave a Reply